IMPEDERS - FERRITES FOR SPECIAL PURPOSES

In industrial production of welded tubes, induction, high-frequency welding of pipes is applied.

The high temperature for welding is ensured by induction of high-frequency current with a working coil and its direction to the welding zone by impedance.

The working coil is made of a copper tube and constructed so that the generated energy from the generator oscillations leads to the welding zone. Impeder directs the energy to the seam of the tube where welding is achieved by the achieved high temperature.

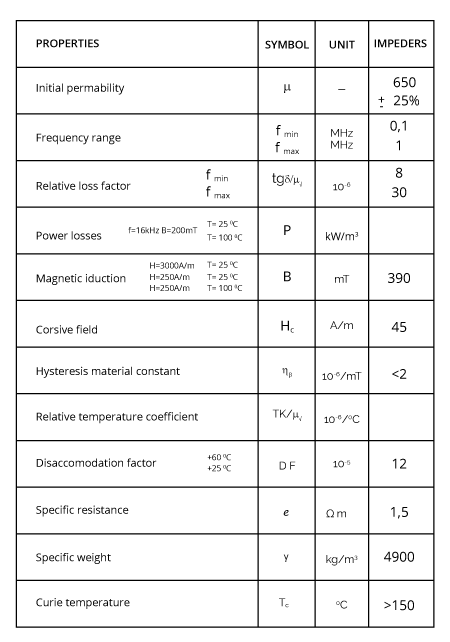

Impeder consists of a housing in which a magnetic field routing core is located - a ferrite core. Characteristics of ferrite cores for impeders are: small magnetic losses, high density of magnetic flux saturation at operating temperature.

Operating conditions of the core for the direction of the magnetic field are: frequency of 100 to 500 kHz magnetic field from 8 to 16 KA / m temperature up to 80 ° C

These impedance operating conditions can only satisfy ferrite magnetic materials, which is why they produce ferrite core for directional magnetic field in high-frequency welding. Maintenance of temperature conditions of impeders is achieved by introducing a suspension for cooling the impeders.

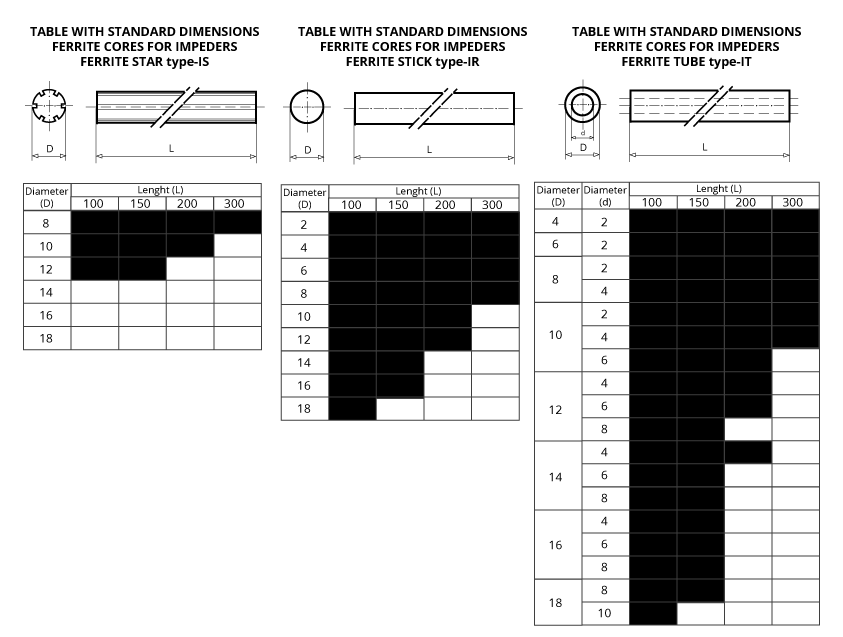

The technology of obtaining ceramic magnetic materials enables the production of ferrite cores of shapes and dimensions in an assortment suitable for satisfying the requirements of the production of welded tubes.

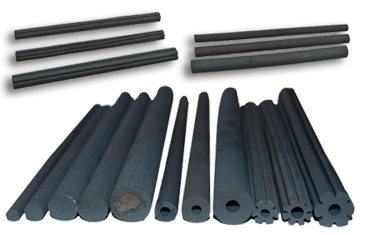

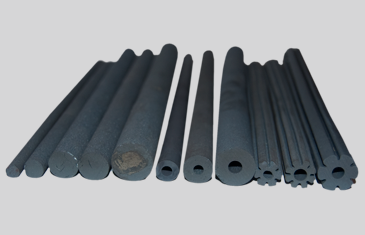

Standard ferrite cores are produced in the form of a rod or tube. In order to increase the efficiency of cooling the ferrite cores in the impeder, ferrite core with a developed surface is produced, that is, with a cross-section in the shape of a star.

If you are interested for our products, please contact us